Find your perfect stainless steel weld on hinges match

Selecting stainless steel weld on hinges involves careful consideration of project-specific factors. TDC stainless steel hinges offer durability and reliability for demanding applications. Users should evaluate weight, usage, and the environment. The table below highlights common requirements for construction and manufacturing projects:

| Requirement | Description |

|---|---|

| Welding Requirements | Requires skilled labor and welding equipment for installation. |

| Permanent Installation | Hinges are permanently welded, making future adjustments labor-intensive. |

| Corrosion Resistance | 304 stainless steel is suitable for mild environments; 316 is needed for marine or highly corrosive conditions. |

| Adjustment Challenges | Difficult to adjust after installation, posing alignment issues. |

Identify Your Project Requirements for Stainless Steel Weld On Hinges

Determine Door or Gate Weight and Size

Selecting the right stainless steel weld on hinges starts with understanding the weight and size of the door or gate. These factors directly influence hinge performance and longevity. For most applications, the following recommendations apply:

1.Recommended door size: 29" x 36"

2.Recommended door weight: 160 lbs

3.Required loading capacity for hinges: 180–200 lbs (using two hinges per door)

A heavy-duty gate hinge must handle the significant force exerted by wide gates, especially at the top hinge, which bears the most weight. The weight of the gate is crucial; if the hinge cannot support it, the gate may sag. For large and heavy doors, heavy-duty, weld-on, or pintle hinges are recommended. Lighter gates can use strap, butt, or barrel hinges. Heavier gates exert more force on hinges, necessitating stronger designs. Weld-on hinges are ideal for heavy metal gates due to their load capacity. Proper hinge selection prevents issues like sagging and scraping.

Weld-on hinges provide a robust and long-lasting hinge solution, ensuring a secure bond capable of withstanding heavy loads.

Assess Frequency of Use and Movement

The frequency of movement impacts the durability and lifespan of stainless steel weld on hinges. Hinges exposed to high-frequency use typically last 5–10 years less than those used occasionally. Choosing hinges designed for the intended level of use ensures better performance and a longer service life.

| Evidence | Explanation |

|---|---|

| Weld-on hinges made from robust metals such as carbon steel and 316 or 304 grades of stainless steel are known for their strength and durability. | These materials enable hinges to withstand heavy loads and constant use, which is crucial for durability in high-frequency applications. |

| Hinges exposed to high-frequency use typically last 5–10 years less than those used occasionally. | This statistic highlights the impact of frequent movement on hinge lifespan, directly addressing the query. |

·Hinges exposed to high-frequency use typically last 5–10 years less than those used occasionally.

·Regular maintenance, such as lubrication and alignment checks, is crucial to prolonging durability.

Consider Environmental Conditions

Environmental factors play a significant role in the performance and longevity of stainless steel weld on hinges. Temperature fluctuations, moisture, airborne contaminants, UV radiation, and chemical exposure can all affect hinge integrity.

| Environmental Factor | Effect on Stainless Steel Welds on Hinges |

|---|---|

| Temperature Fluctuations | Can cause expansion and contraction, affecting weld integrity. |

| Moisture | Leads to rusting and corrosion, especially if iron is present. |

| Airborne Contaminants | Can cause faster wear and corrosion through chemical reactions. |

| UV Radiation | Degrades lubricants and protective coatings, increasing wear. |

| Chemical Exposure | Accelerates corrosion and degradation of hinge materials. |

Temperature extremes and humidity levels are critical factors in selecting stainless steel weld on hinges. High humidity can accelerate corrosion, while temperature fluctuations can lead to warping or structural degradation. Stainless steel, particularly grades 304 and 316, is favored for its corrosion resistance and ability to maintain mechanical integrity in harsh conditions.

·304 stainless steel hinges are effective in moderate humidity, providing good corrosion resistance.

·316 stainless steel hinges are ideal for highly corrosive environments, offering superior resistance to chloride corrosion, making them suitable for marine applications.

Stainless Steel Weld On Hinges Grades and Their Benefits

Common Grades: 304 vs 316

When selecting stainless steel weld on hinges, understanding the differences between 304 and 316 grades is essential. These two grades dominate the market due to their unique properties and performance in various environments.

| Property | 304 Stainless Steel | 316 Stainless Steel |

|---|---|---|

| Tensile Strength | Moderate | High |

| Hardness | Moderate | High |

| Modulus of Elasticity | High | Lower |

| Corrosion Resistance | Good | Superior |

304 stainless steel offers flexibility and moderate strength, making it suitable for most general applications. 316 stainless steel contains molybdenum, which increases its resistance to chloride pitting. This feature makes 316 the preferred choice for marine environments, chemical processing plants, and industrial facilities exposed to saltwater spray.

·304 stainless steel provides decent corrosion resistance but performs best in mild to moderate conditions.

·316 stainless steel excels in harsh, corrosive settings, especially where salt or chemicals are present.

Corrosion Resistance and Strength

Corrosion resistance and strength define the performance of stainless steel weld on hinges in demanding settings. The following table highlights typical corrosion resistance ratings:

| Stainless Steel Grade | Corrosion Resistance | Notes |

|---|---|---|

| 304 | Moderate | General use, less resistant to chlorides |

| 316 | High | Contains molybdenum, better for harsh environments |

304 stainless steel works well in humid conditions but may not withstand marine exposure. 316 stainless steel stands out in corrosive environments, including marine and chemical applications, due to its superior resistance.

Stainless steel hinges deliver a high strength-to-weight ratio. They support heavier loads while maintaining a thinner profile compared to other materials. This advantage makes them ideal for heavy-duty gates and doors in commercial and industrial settings.

Types of Stainless Steel Weld On Hinges and Applications

Standard Barrel Hinges

Standard barrel hinges serve as a reliable choice for many industrial and commercial projects. These hinges feature a cylindrical design that allows smooth pivoting and secure attachment. Users often select barrel hinges for their versatility and strength. Common applications include:

·Industrial machinery, such as machine panels and access doors

·Heavy gates and commercial doors

·Marine environments, including ship doors and dockside equipment

·Trailer ramps for loading and unloading

·Steel doors in industrial and commercial buildings

Barrel hinges come in various sizes and load capacities to suit different requirements. The following table highlights typical size options:

| Size (inches) | Load Capacity (lbs) |

|---|---|

| 4 | N/A |

| 5 | N/A |

| 6 | N/A |

| 7 | N/A |

Load capacities range from 400 lbs to 40,000 lbs, making these hinges suitable for both light and heavy-duty tasks.

Heavy-Duty Hinges

Heavy-duty weld-on hinges deliver exceptional performance in demanding environments. Their welded joints distribute stress evenly and minimize movement. These hinges feature thicker construction, often 6 mm or more, which increases resistance to shear and torsion. Heavy-duty models withstand high torque and radial loads without deforming. They eliminate play and can operate for over 500,000 cycles, making them ideal for high-shock applications.

Industries that frequently use heavy-duty hinges include:

·Agriculture

·Construction

·Medical

·Military and Defense

·HVAC

·Food Processing

·Aerospace

·Shipping and Logistics

Manufacturers design these hinges for durability and security. They use strong metals like 304 or 316 stainless steel and add coatings to resist corrosion. Heavy-duty hinges support extremely heavy doors, with capacities from 1,000 lbs up to 40,000 lbs.

Specialty Hinges

Specialty stainless steel weld on hinges address unique project challenges. These hinges provide permanent attachment to metal surfaces and eliminate the need for drilling or bolting. They offer tamper resistance and withstand heavy loads and harsh conditions. Specialty hinges find use in a wide range of applications:

| Application | Description |

|---|---|

| Truck Body | Secure attachment and heavy load capacity |

| Trailer | Durability for mobile applications |

| Storage | Reliable hinges for storage units |

| Refrigeration | Functionality in cold environments |

| BBQ Grills | Robust performance in high temperatures |

| Food Equipment | Hygiene and durability for food service |

| Waste Disposal | Heavy-duty use in waste management |

| Framing | Structural support in construction |

| Gates | Security and ease of use for entry points |

| Other Applications | Versatile for additional uses |

Specialty hinges provide durability, corrosion resistance, and customization options to meet specific needs.

Sizing and Load Capacity for Stainless Steel Weld On Hinges

Calculating Required Hinge Size and Number

Project planners must determine the correct hinge size and number to ensure safe and reliable operation. The process begins with measuring the door thickness and width. Next, they use a hinge sizing calculator to identify the required hinge height. The overall hinge width is calculated using the formula:

(Door thickness – backset) x 2 + required clearance = overall hinge width.

The following table provides guidance for selecting the number of hinges based on door height:

| Door Height | Number of Hinges |

|---|---|

| Up to 60" (1524 mm) | 2 Hinges |

| Over 60" and not over 90" (2286 mm) | 3 Hinges |

| Over 90" and not over 120" (3048 mm) | 4 Hinges |

| Extra hinge for doors 37" to 48" (940–1220 mm) | 1 Extra Hinge |

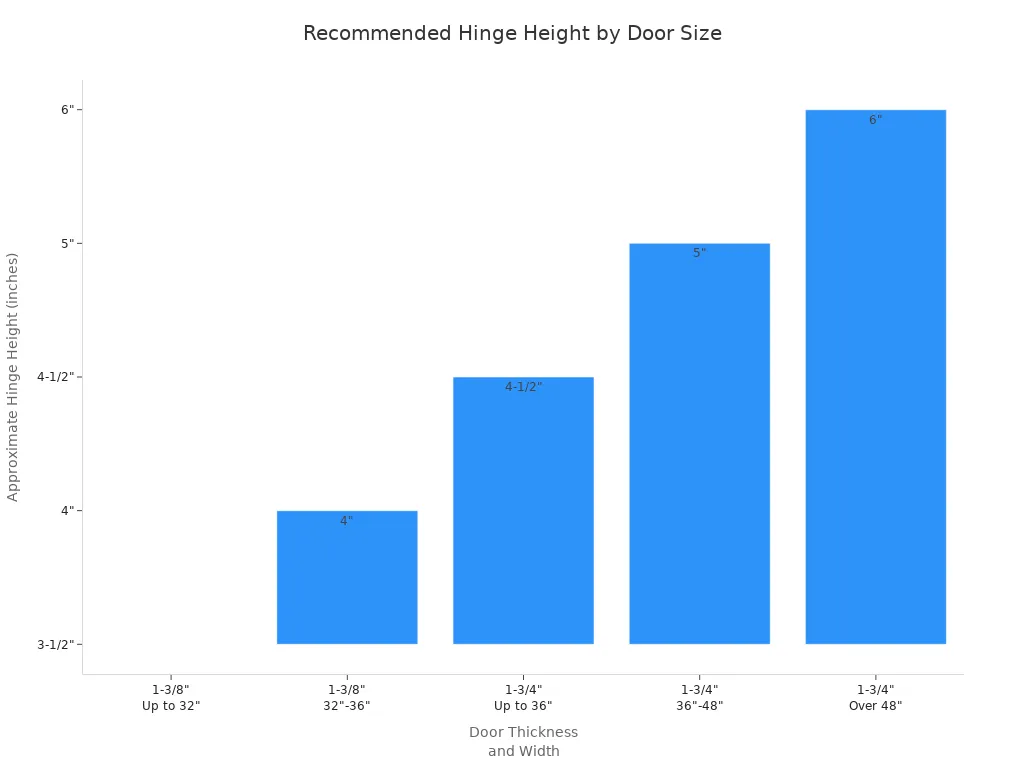

Door thickness and width also influence hinge height selection:

| Door Thickness | Door Width | Approximate Hinge Height |

|---|---|---|

| 1-3/8" | Up to 32" | 3-1/2" |

| 1-3/8" | 32"-36" | 4" |

| 1-3/4" | Up to 36" | 4-1/2" |

| 1-3/4" | 36"-48" | 5" |

| 1-3/4" | Over 48" | 6" |

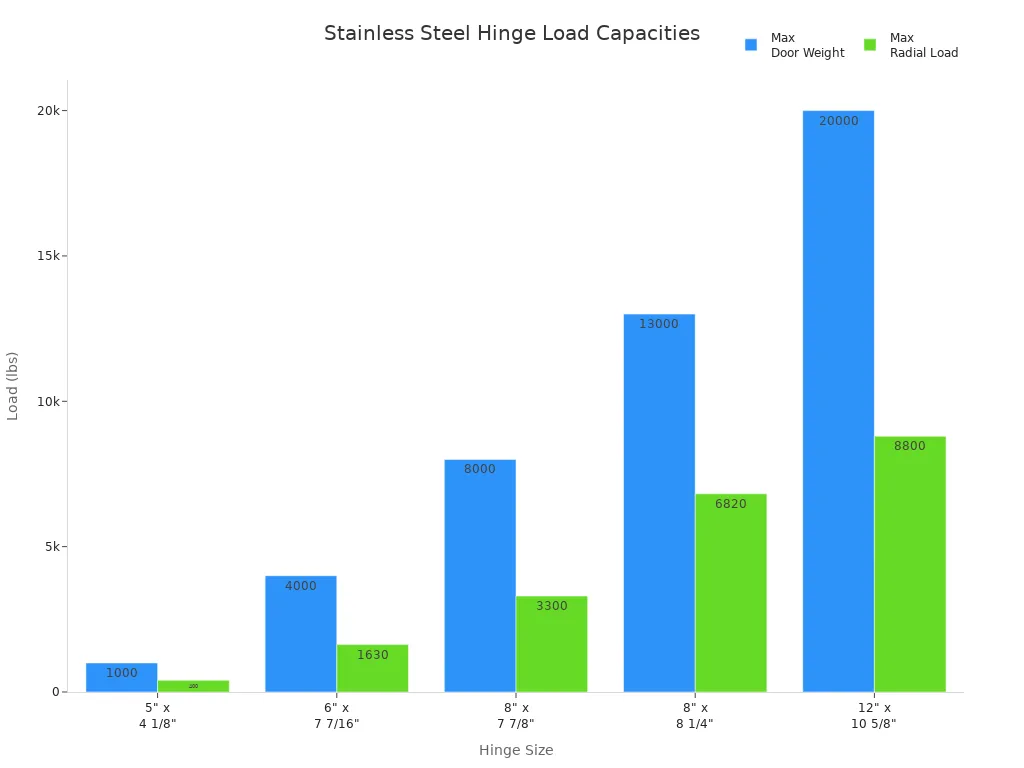

Matching Hinge Capacity to Project Demands

Engineers must match hinge capacity to the specific demands of each project. The load capacity depends on hinge material, size, number of hinges, and the door’s weight and dimensions. Heavier doors require stronger hinges, especially when frequent use is expected. The table below shows recommended load capacities for stainless steel weld on hinges in various sizes:

| Hinge Size | Maximum Door Weight | Maximum Radial Load |

|---|---|---|

| 5" x 4 1/8" | 1,000 lbs | 400 lbs |

| 6" x 7 7/16" | 4,000 lbs | 1,630 lbs |

| 8" x 7 7/8" | 8,000 lbs | 3,300 lbs |

| 8" x 8 1/4" | 13,000 lbs | 6,820 lbs |

| 12" x 10 5/8" | 20,000 lbs | 8,800 lbs |

Manufacturers conduct mechanical load testing, cycle testing, and environmental testing to ensure hinges meet safety and longevity standards. Industry certifications such as ANSI/BHMA and ISO 9001 confirm quality and performance. By following these guidelines, project managers can select hinges that deliver reliable support and long-term durability.

Installation Considerations for Stainless Steel Weld On Hinges

Welding Compatibility and Techniques

Proper welding ensures the longevity and strength of stainless steel weld on hinges. Installers often select MIG welding for its versatility and ability to create robust, clean welds on thicker metal hinges. MIG welding works well with grade 304 stainless steel, which is commonly used in weldable hinges. TIG welding offers precise control, making it suitable for projects that require a refined finish. Stick welding remains a reliable choice for outdoor installations and thicker materials. Each method requires attention to heat input and shielding gas selection to prevent warping and maintain corrosion resistance.Stainless-steel barrel hinges provide high corrosion resistance, making them ideal for demanding environments.Proper welding techniques lead to strong and aesthetically pleasing welds.Common welding methods for stainless steel weld on hinges:

·MIG welding: Delivers powerful, versatile joints for grade 304 stainless steel.

·TIG welding: Offers greater control and precision for stainless steel hinges.

·Stick welding: Performs well outdoors and with thicker materials.

Alignment and Maintenance Tips

Accurate alignment during installation prevents operational issues and extends hinge life. Installers should check hinge placement before welding to ensure smooth movement. After installation, regular maintenance helps preserve performance and appearance.

Maintenance tips for stainless steel weld on hinges:

·Lubricate hinges with silicone-based products to reduce friction and prevent rust.

·Clean hinges regularly to remove debris and maintain smooth operation.

·Inspect hinges for signs of wear or damage.

·Apply protective coatings to enhance durability.

·Conduct post-weld cleaning to protect against oxidation.

·Replace hinges when necessary to maintain functionality.

Regular inspection and lubrication help manage environmental factors and prevent oxidation.Proper cleaning and protective coatings increase the lifespan of hinges in harsh conditions.

Quick Reference Checklist for Choosing Stainless Steel Weld On Hinges

Project managers and engineers rely on a checklist to streamline the selection of stainless steel weld on hinges. A well-organized checklist helps teams avoid costly mistakes and ensures every requirement receives attention. The following table summarizes the essential items to review before making a final decision:

| Essential Item | Description |

|---|---|

| Material and grade | Select the appropriate stainless steel grade for the environment |

| Finish type and durability | Evaluate finish options based on exposure and longevity |

| Load ratings and safety factors | Confirm hinges support the intended weight and meet safety standards |

| Installation method | Choose weld-on, bolt-on, or screw-on based on project needs |

| Hole pattern and screw size | Verify compatibility with existing structures |

| Adjustability and pin type | Assess if hinge adjustments or specific pin types are required |

| Warranty terms | Review warranty coverage for long-term reliability |

A checklist improves the selection process by guiding users through critical steps. Teams should consider specifications, material selection, hinge types, and load capacity. Safety requirements and quality standards play a vital role in industrial projects. Quantity, delivery time, and budget also influence the final choice. Samples or technical drawings help confirm compatibility. Requesting a quotation ensures transparency and cost control.

Tip: Always compare product samples and technical drawings before placing an order. This step helps prevent installation issues and ensures the hinges meet project specifications.

A comprehensive checklist supports efficient decision-making and guarantees that stainless steel weld on hinges deliver optimal performance in every application.

Selecting stainless steel weld on hinges involves several key steps:

1.Inspect surface quality and ensure smooth operation.

2.Check rivet tightness and screw quality.

3.Avoid deep indentations.

·Regular cleaning and specialized lubricants maintain performance.

·Routine inspections and proper material selection ensure long-term durability.

Matching hinge features to project needs delivers reliable results.

FAQ

What grade of stainless steel should they choose for outdoor gates?

304 suits mild climates. 316 resists salt and chemicals. TDC recommends 316 for marine or industrial environments. Users should match grade to exposure level.

Tip: Always confirm environmental conditions before selecting hinge grade.

How many weld on hinges does a heavy door require?

Most heavy doors need at least three hinges for stability. TDC suggests checking door height and weight before finalizing the number.

| Door Height | Recommended Hinges |

|---|---|

| Up to 60" | 2 |

| Over 60" | 3 |

Can users install TDC stainless steel weld on hinges themselves?

Experienced welders can install TDC hinges. Beginners should consult professionals for safety and proper alignment. TDC provides installation guides for reference.

Note: Proper welding ensures hinge durability and performance.

Related articles

-

How to Fit Concealed Hinges Without Stress or Mess

Step-by-step guide on how to fit concealed hinges for a flawless, mess-free finish. Avoid common mistakes and achieve professional results every time.Sep-19-2025 Learn More >> -

A Homeowner’s Guide to Picking the Right Door Gate Hinges

Choose door gate hinges that fit your door, support its weight, and match your environment for secure, long-lasting performance in any home project.Sep-19-2025 Learn More >> -

How to Fit Concealed Hinges and Ditch Old Myths

How to fit concealed hinges with precision: step-by-step guide, pro tips, and common mistakes to avoid for flawless cabinet door alignment every time.Sep-19-2025 Learn More >>

To Provide You with Better Service

Contact

Tel: +8613325838282

Add: 6265 Providence Way Eastvale,CA 92880