Data-Backed Secrets to Selecting Stainless Steel Hinges

Data-Backed Secrets to Selecting Stainless Steel Hinges

Selecting the correct stainless steel hinges is a critical engineering decision that directly impacts a project's durability and safety.

Professionals must match a hinge’s load capacity to the project’s weight. Choosing the right stainless steel hinges grade is vital for environmental resistance. The pin configuration also determines security and maintenance needs for all stainless steel hinges.

.jpg)

Calculate Your Project's Load Capacity

Accurate load capacity calculation is the most critical engineering parameter for hinge selection. It ensures the structural integrity and long-term performance of any door, gate, or lid. An incorrect calculation can lead to premature failure, posing significant safety risks and incurring costly repairs. Professionals must precisely determine the forces at play to select stainless steel hinges that can safely support the load for the project's entire lifespan.

Measure Weight and Dimensions

The first step is to determine the total weight and dimensions of the object the hinges will support. An engineer needs the exact weight of the door or gate. They also need its height and width. These measurements are fundamental inputs for calculating the required hinge strength.

The number of hinges directly impacts how this weight is distributed. Using more hinges spreads the load, reducing the stress on any single hinge. For very heavy or wide gates, professionals often use specific hinge types to manage the load effectively. Continuous hinges, for example, run the full length of the door and distribute weight evenly to prevent sagging. Similarly, strap hinges feature long plates that extend across the door's surface, providing excellent support. For such heavy-duty applications, products like the TDC-0030 Weld On Hinge or the TDC-0031 Weld On Hinge offer the necessary strength and stability.

Pro Tip: Engineers often use standard formulas to guide their selection. While specific manufacturer guidelines are paramount, these calculations provide a reliable starting point:

Hinge Capacity = Total Door Weight / Number of Hinges

Hinge Size (inches) = (Door Height × Door Weight) / 1000

Add a Safety Margin

A safety margin is not optional. It is a foundational requirement for safety and longevity. This margin ensures a hinge can withstand unexpected stresses, dynamic forces from movement, and the cumulative effects of wear over time.

For general applications, a hinge's load capacity should be at least 25% greater than the calculated weight. However, this margin increases significantly based on the application's demands.

Industrial applications often require a safety factor of 4:1, meaning the hinge should be rated for four times the expected load.

Aerospace applications demand an even higher safety factor, typically around 8:1, where failure is not an option.

This safety buffer is especially critical for high-frequency use. Doors in commercial or public buildings endure immense stress from repeated opening and closing cycles. Heavy-duty hinges are engineered to handle these forces, ensuring operational efficiency and minimizing downtime.

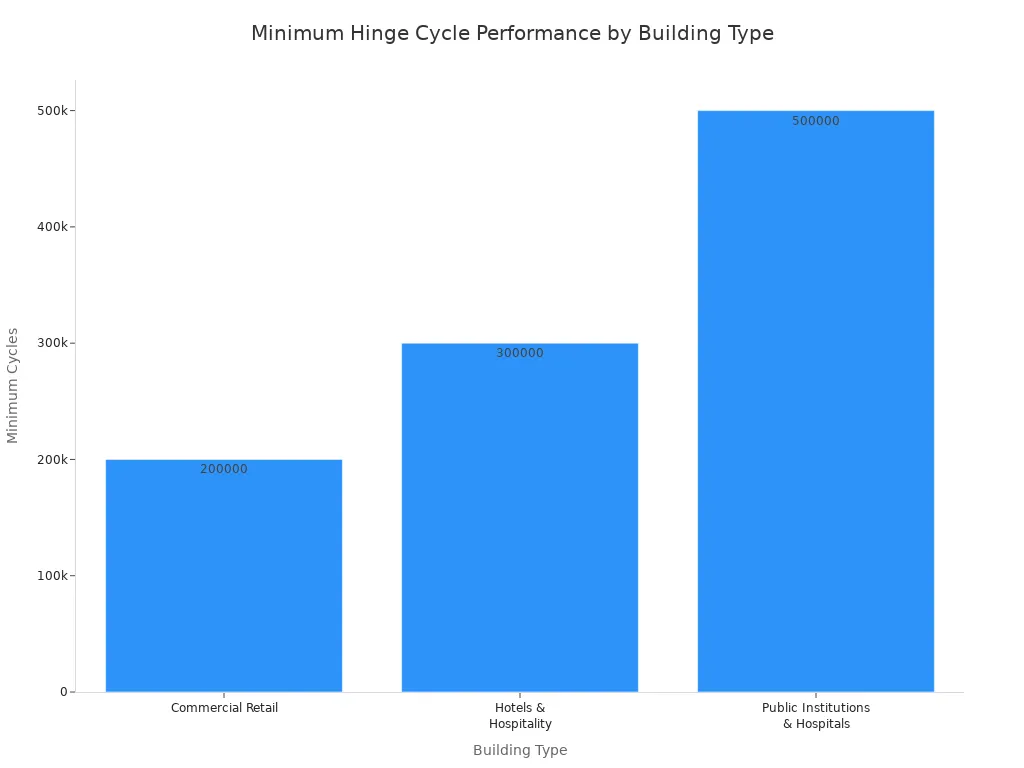

| Building Type | Minimum Cycle Performance |

|---|---|

| Commercial Retail | 200,000 cycles |

| Hotels & Hospitality | 300,000 cycles |

| Public Institutions & Hospitals | 500,000 cycles |

Ignoring an adequate safety margin leads to predictable and expensive problems.

Prevents door sagging and frame misalignment.

Reduces long-term maintenance costs.

Enhances user safety and accessibility.

Avoids operational downtime in busy environments.

Ultimately, selecting a hinge with a robust safety margin is an investment in reliability and safety.

Select the Right Stainless Steel Grade

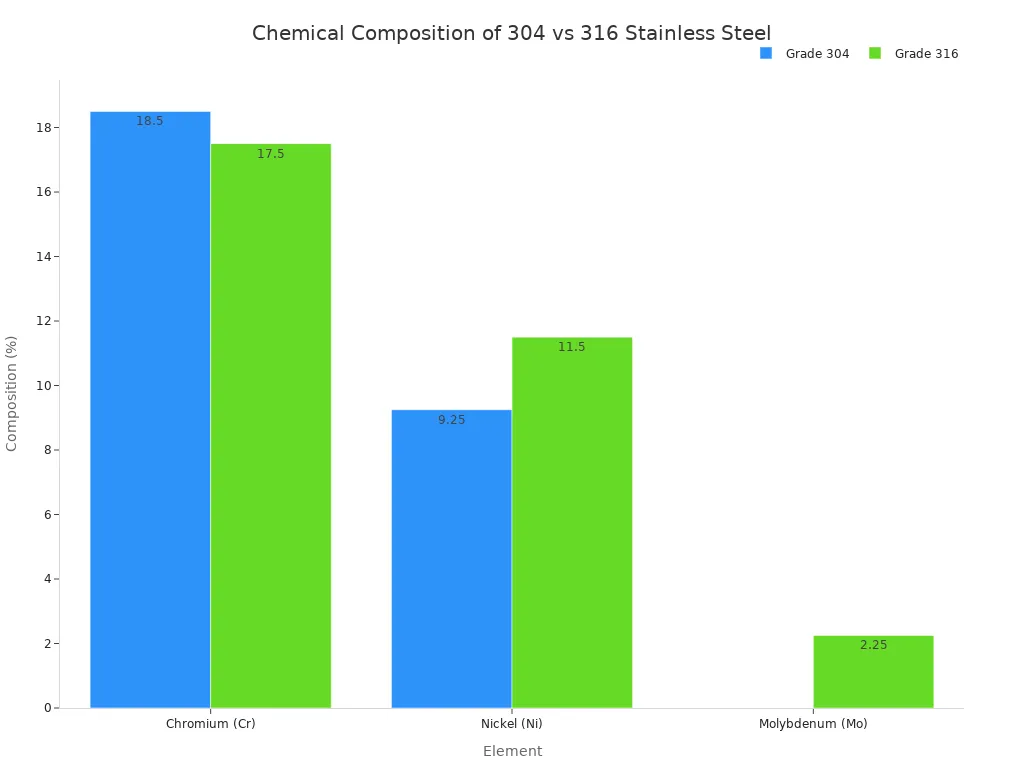

Choosing the correct stainless steel grade is a critical decision that directly influences a hinge's lifespan and performance. The primary options, Grade 304 and Grade 316, have distinct chemical compositions that make them suitable for different environments. The choice is not about which grade is better, but which is appropriate for the specific application.

The fundamental difference lies in their elemental makeup. Grade 304 stainless steel typically contains 18% chromium and 8% nickel. In contrast, Grade 316 contains 16% chromium, 10% nickel, and a crucial addition of 2% molybdenum. This molybdenum is the key element that gives Grade 316 its superior corrosion resistance.

Grade 304 for General Use

Grade 304 is the most common and versatile stainless steel. Its composition provides excellent corrosion resistance for a wide array of applications. Professionals consider it the industry standard for most indoor and standard outdoor environments.

For projects not exposed to extreme moisture, salt, or corrosive chemicals, Grade 304 offers an ideal balance of performance, durability, and cost.

This grade is sufficient for many common uses. It performs reliably in residential and commercial buildings, for interior doors, cabinets, and general-purpose gates. In a standard residential setting, a quality Grade 304 hinge can have an expected lifespan of over 15 years. Its widespread use makes it a more economical choice. Grade 316 stainless steel hinges typically cost about 40% more, making Grade 304 a cost-effective solution where advanced protection is unnecessary.

Grade 316 for Harsh Environments

Grade 316 stainless steel is the mandatory choice for harsh and corrosive environments. The inclusion of molybdenum significantly enhances its ability to resist pitting and corrosion, especially from chlorides found in saltwater and de-icing salts. This superior resistance is quantifiable. The Pitting Resistance Equivalent Number (PREN) for Grade 316 is around 24-26, while Grade 304's is only 18-20.

Using the wrong grade in these settings leads to premature failure. Grade 304, when used in coastal areas, quickly develops unsightly brown rust spots and pitting. Case studies from industrial settings show similar failures.

A seafood processing plant saw severe pitting in its 304L piping systems within two years due to high chloride concentrations.

An equipment integrator discovered crevice corrosion on 304 tubing under pipe clamps caused by stagnant water and sanitizing chemicals.

For this reason, certain industries require Grade 316 hardware as a non-negotiable standard. These applications include:

Marine and coastal construction (boat fittings, docks)

Chemical processing equipment

Food and beverage preparation areas

Pharmaceutical and laboratory equipment

Wastewater treatment plants

While Grade 316 comes at a higher price point, it is a necessary investment for safety and longevity in demanding conditions. The table below summarizes the key distinctions for a final decision.

| Feature | 304 Stainless Steel | 316 Stainless Steel |

|---|---|---|

| Main Use | General Purpose, Indoor | Marine, Chemical, Medical |

| Molybdenum | No | Yes (2-3%) |

| Saltwater Resistance | Poor | Excellent |

| Cost | Lower | Higher |

Selecting the right grade ensures the hinge not only supports the load but also withstands its environment for years to come.

Choose the Optimal Pin Configuration

The hinge pin is the pivot point of the entire assembly. Its configuration determines both the security and serviceability of the door or gate. Professionals must choose a pin type that aligns with the project's specific access and security requirements. The decision between a fixed or loose pin directly impacts how the hinged object can be installed, maintained, and protected from tampering.

Fixed Pins for Security

Fixed pins are permanently secured within the hinge barrel, making them impossible to remove without destroying the hinge. This design offers maximum security, as it prevents intruders from simply tapping out the pin to remove a door. For high-security applications, engineers often specify additional protective features.

Non-Removable Pins: The pin is staked or welded in place, preventing detachment.

Security Studs: These studs on one hinge leaf interlock with the other when closed, keeping the door secure even if the pin is compromised.

Interlocking Tabs: These tabs engage upon closing, creating a robust barrier against forced removal.

These features make fixed-pin hinges the standard for exterior doors, security gates, and any access point where preventing unauthorized entry is a top priority.

Loose Pins for Convenience

Loose pin hinges feature a removable pin. This design allows for the quick and easy separation of the two hinge leaves. It is ideal for applications requiring frequent removal of a door or panel for maintenance, transport, or access.

Pro Tip: For interior doors that may need to be removed for moving furniture or for maintenance access panels, a loose pin offers unmatched convenience. The TDC-0032 Weld On Hinge is an excellent example of a product designed for such flexible applications.

While convenient, this configuration is not suitable for out-swinging exterior doors, as the exposed pin could be easily removed from the outside.

Select the Right Pin Material

The pin material directly affects a hinge's longevity and resistance to wear. A pin made from a dissimilar or inferior metal can cause galling or premature failure. Using a high-quality pin material ensures the hinge withstands repeated stress and environmental factors. For most industrial uses, 304 stainless steel provides a superior balance of corrosion resistance, strength, and cost-effectiveness. However, for applications with extreme wear, other materials offer better performance.

| Pin Material | Key Property | Longevity Impact |

|---|---|---|

| 304/316 Stainless | Good corrosion resistance | Standard longevity; can gall against itself |

| Hardened 420 Stainless | High hardness (52-54 RC) | Excellent; pin will outlast the hinge leaves |

| 17-4 PH H900 | High strength, good hardness | Very good longevity and galling resistance |

Selecting a hardened pin material like 420 stainless steel is a critical engineering choice for ensuring maximum durability in high-cycle environments.

Match Hinge Type to Your Application

Selecting the right hinge type is as important as choosing the correct material grade. The hinge's design must align with the application's structural needs, weight distribution, and aesthetic goals. Weld-on hinges offer permanent, high-strength solutions, but different styles serve distinct purposes.

Weld-On Butt Hinges

Weld-on butt hinges are the workhorses of heavy-duty industrial applications. Their design allows for direct welding to the frame and door, creating an exceptionally strong, tamper-proof connection. This permanent bond distributes force effectively, eliminating common failure points associated with mechanical fasteners.

For heavy gates, industrial machinery, and security doors, butt hinges provide unmatched reliability. Products like the TDC-0030 Weld On Hinge and TDC-0031 Weld On Hinge are engineered for these demanding environments.

Their primary advantages include:

Superior Strength: They handle significant weight without loosening over time, even with constant vibration.

Enhanced Security: The welded connection is permanent and highly resistant to tampering.

Durability: They offer excellent resistance to rust and corrosion, reducing maintenance and replacement costs.

Weld-On Bullet Hinges

Weld-on bullet hinges offer a clean and streamlined appearance, making them a popular choice for projects where aesthetics are a priority. Their compact, cylindrical shape is inconspicuous, contributing to a sleek and modern look. These hinges are ideal for custom gates, cabinets, and metal enclosures where a low-profile design is desired. The TDC-0032 Weld On Hinge is a prime example of this sleek and functional design.

Weld-On Strap Hinges

Weld-on strap hinges are characterized by their long leaves, or "straps," which extend across the surface of a door or gate. This design provides superior support by distributing the load over a much wider area. It is the ideal solution for very large, heavy, or wide structures like barn doors and agricultural gates, as it effectively prevents sagging over time. The extended straps add structural reinforcement, ensuring long-term stability for the heaviest applications.

Key Considerations for Stainless Steel Hinges

Beyond selecting the right type, professionals must evaluate specific physical dimensions and installation methods. These final details ensure the hinge performs optimally and maintains its structural integrity throughout its service life.

Barrel and Leaf Dimensions

The dimensions of a hinge's barrel and leaves are critical engineering specifications. The barrel's diameter and length directly influence the pin size and the hinge's overall load-bearing capacity. A larger barrel can accommodate a stronger pin, making it suitable for heavier applications.

Similarly, the leaf thickness and surface area determine the strength of the connection. Thicker leaves provide greater rigidity and resistance to bending. Wider leaves offer a larger surface area for welding, which creates a stronger, more durable bond between the hinge and the structure. Professionals must verify these dimensions are sufficient for the calculated load.

Proper Welding Techniques

Proper welding is essential to preserve the corrosion resistance and strength of stainless steel hinges. Incorrect techniques can compromise the material, leading to premature failure. Welders should follow the guidelines established by the American Welding Society, particularly the AWS D1.6/D1.6M: Structural Welding Code – Stainless Steel.

Professionals must avoid common mistakes that weaken the final assembly. Stainless steel has different thermal properties than carbon steel and requires specific procedures.

Common errors to avoid include:

Using Excessive Heat: Too much heat depletes chromium near the weld, causing "weld decay" and reducing corrosion resistance.

Cross-Contamination: Using tools or grinding wheels previously used on carbon steel can introduce iron particles, leading to rust.

Incorrect Filler Material: Welders must use the correct filler rod, such as a 309 rod for joining stainless to mild steel, to prevent cracking.

Wrong Shielding Gas: A gas mixture with high carbon dioxide content can compromise the weld's integrity.

Adhering to correct procedures ensures the weld is as strong and corrosion-resistant as the hinge itself.

Professionals can finalize their selection with confidence by using a final verification checklist. This systematic review ensures the chosen stainless steel hinges meet all critical engineering parameters for safety and longevity.

Load Capacity: Ensure the hinge rating exceeds the calculated load by at least 25%.

Steel Grade: Choose Grade 304 for standard conditions and 316 for corrosive settings.

Pin Type: Select a fixed pin for security or a loose pin for easy removal.

Welding: Confirm the use of correct filler rods and techniques.

FAQ

How much stronger should a hinge be than the door?

A hinge's load capacity must exceed the calculated weight by at least 25%. This essential safety margin prevents failure and ensures long-term structural integrity.

When is Grade 316 stainless steel necessary?

Professionals must use Grade 316 stainless steel in marine or chemical environments. Its molybdenum content provides superior resistance to salt and other corrosive elements.

What filler rod joins stainless hinges to mild steel?

Welders should use a 309 filler rod to join stainless steel hinges to mild steel. This specific rod prevents cracking and ensures a strong, durable bond.

Related articles

-

.jpg)

How to Install Hidden Residential Hinges A Step-by-Step Guide

Follow our guide to install hidden residential hinges. We cover preparing the door, installing the hinge and mounting plate, and making final adjustments.Nov-18-2025 Learn More >> -

.jpg)

Flawless Finishes How to Fit Concealed Hinges Fast

Get a flawless finish by learning how to fit concealed hinges with precision. This guide covers using a jig, drilling accurate cup holes, and making adjustments.Nov-18-2025 Learn More >> -

Key Features to Check Before Buying Door Gate Hinges

Select the right door gate hinges by calculating load capacity and choosing a material like stainless steel for durability. Consider the hinge type and pin for security.Nov-18-2025 Learn More >> -

Why Modern Homes Demand Upgraded Security Hinges

A standard door hinge is a weak point intruders exploit to bypass locks. A security hinge with non-removable pins and deep anchoring prevents this, securing the door.Nov-18-2025 Learn More >>

To Provide You with Better Service

Contact

Tel: +8613325838282

Add: 6265 Providence Way Eastvale,CA 92880